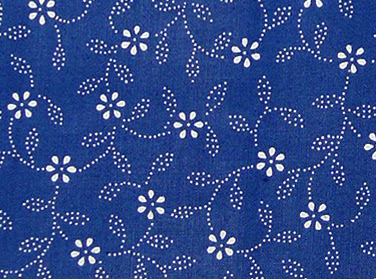

This fabric is called Kékfestö in Hungarian, a word that roughly translates as blue-dyed or blue-dying. Producing these fabrics is a cottage industry in Hungary, which dates back several centuries. The dye is indigo; the cloth is cotton; and the long, arduous process results in a type of batik fabric. The photo above shows a small fold of each of the fabrics I bought at the blue-dyed studio shown below. (As always, please click on the photos if you'd like to see more detail.)

When in Hungary in October, 2016, my quilting/travel friend (Lunnette) and I, as guests of my Hungarian bead sister, Anna Fehér, had the very exciting experience of visiting the hand-dying studio of Miklós Kovács in the little village of Tiszakécske, SE of Budapest. The studio, located behind his home, includes two rooms, one for printing the raw cloth with a wax resist, and the second for dying the printed cloth with indigo. In front of the building, you can see rods above the deck, which are used for hanging the fabric to dry after it is dyed, and a wagon loaded with printed cloth ready to be dyed.

Meet Mr. Miklós Kovács, now in his 80s! Charming and animated, he is explaining his traditional, hand-dying process to Anna. Blue-dying has been the Kovács family's livelihood since 1878, each new generation being trained by the previous Master. It is strictly a family affair. Miklós, his wife, Margit, and their two daughters, Gabriella and Mária, currently produce about 10,000 meters of Kékfestö (blue-dyed) fabric every year. When Mr. and Mrs. Kovács retire, the business will pass to their daughters. This post shows how they turn plain white cloth into beautiful fabrics with white motifs on an indigo background.

First, they need thousands of meters of fine-quality, tightly-woven, raw cotton cloth, which is rinsed to remove impurities, then carefully ironed and rolled onto wooden rods which fit onto the printing machine. This pile of untreated cotton cloth, manufactured in Turkey, is the remainder of a big shipment purchased at the start of the year.

Next they need a print block or plate. These are made with wire pins of various diameters, which are pounded into blocks of dense wood. Here you see the many plate choices available in the Kovács studio, each yielding a different motif on the fabric. The length of each print block is the same as the width of the fabric; the width is the width of the pattern repeat, generally designed to be about 4.5 inches..

This is the end of one of the print blocks, showing how the design is formed by setting metal pins of different diameters into the wooden block.

And here is the fabric (after dying it with indigo, and removing the wax resist), which was printed with the block in the photo above it. Naturally, a half-meter of this one came home with me!

This is the machine which is used to print the motif on the raw cotton cloth with a wax resist. Mr. Kovács keeps his printing machine, built in Germany 120 years ago, in good running condition with machinist skills he learned alongside his father.

You can see the sprocket, lower right, which is adjusted to advance the fabric through the machine in increments exactly the length of the pattern repeat. For most motifs, the fabric advances 4 to 5 inches after each time the print block is applied to the fabric, thus revealing the next short stretch of un-printed cloth.

Here you can see many meters of raw cotton cloth, suspended on a metal rod at the back of the printing press. There is a leader of waste cloth stitched to the end of the roll which has been fed through the rollers of the machine to get the process started.

At the front of the printing machine, a worker swipes a tray with wax resist, which is tinted green so that it will be visible on the printed cloth. The printing block touches down on the waxed tray, picks up a coating of was, and then presses firmly against the fabric.

After being imprinted with wax resist, the fabric is wound up and down through a drying rack located behind the printing machine.

When it is dry, the printed fabric is folded and stacked until there is a sufficient quantity to begin the dying process. You can see that some of the raw cloth in this pile was pre-dyed pink, blue, or beige. After over-dying with indigo and removing the resist, the motif on these pieces will be pink, blue or beige with an indigo background, rather than the much more common white motif with an indigo background.

This close-up photo shows how the fabric looks after the wax resist (tinted green so that is shows on white cloth) is dry. This is the motif being printed while we were there. Liking the design a lot, I was very pleased to find finished fabric in this pattern available to purchase.

And this is how the cloth will look after it is dyed with indigo, the wax resist removed, and the fabric washed and ironed. As you might have already guessed, a half-meter of this one came home with me!

As we watch the cloth passing slowly through the rollers of the printing machine, Lunnette holds a scrap of dyed fabric which was tied to the machine, indicating the motif currently being printed.

At last, we get to the dye pot! Here on the burner, a concentrated indigo dye formula is being readied to pour into the dye vat.

Don't forget to wear those heavy rubber gloves, or the skin on your hands will be tinged with blue for a long time.

Mr. Kovács gave a long, animated talk (all in Hungarian, which I only slightly comprehend) about the whole process of blue dying. You've already seen how the cloth is printed with wax resist. The next step is to dye the background.

The cloth is dyed in a vat with the indigo dye-bath at 85 degrees

C., then washed to remove the wax and rinsed to remove the excess dye.

After rinsing, the cloth is looped over racks to dry outdoors, which

completes the dying process. Sadly, he did no dying while we were there, so I don't have pictures

or first-hand experience with precisely how it is done to share with

you.

However the fabric is not yet ready to use. It must be starched, dried,

and then pressed using both steam and steel rollers with heavy pressure,

in order to create the traditionally desirable shiny finish on the

cloth. Finally, the fabric is folded onto bolts for distribution to

shops and end-users.

We learned how they hand-print motifs on cloth using a template, such that after dying, the fabric can be cut out and hemmed as a finished table cloth. You can see the templates hanging on the wall. The desired template is placed over the fabric, and a pencil used to mark the registration points for lining up the printing block. Fabrics which have already been printed are stacked in front of the templates. After being dyed, this fabric will be made into table cloths and runners of various sizes.

This is a section of cloth which as been marked with a template, and hand-stamped with wax resist. After dying with indigo and removing the wax, it will be made into a rectangular table cloth with a lovely double border all the way around.

Mrs. Kovács demonstrates for us how she lines up the print block with the penciled registration marks, and then lowers it onto the fabric. With the stamp resting on the cloth, she lightly pounds it with her fist to set the wax into the fabric. It was obvious to us that carefully making each wax impression all the way around the cloth takes a lot of time and concentration. As you an see below, the results of her hand-printing are stunning!.

Here is an example of a hand-stamped, indigo-dyed fabric made into a round table cloth. Obviously, it came home with me, and is perfect for my kitchen table! This fabric is quite wide, and takes a great deal of space and time to print. Yet, the prices were very reasonable!

After spending several hours in the studio, we were invited to the house for a shopping bonanza! Fortunately, hoping ahead of time that we would be visiting a Kékfestö studio when we got to Hungary, we had saved our allowances for some months, and were prepared to shop for future quilting and sewing projects. The prices, ranging $10 to $15 per meter depending on the width, seemed very reasonable considering the quality of the fabric, and the extreme amount of work that goes into producing it.

In addition to yardage, both of us bought a table cloth and an apron. Mine is shown above.

What a totally delightful experience we had! Mr. and Mrs. Kovács are as friendly and nice as can be! If you ever get to Hungary, you can find their fabrics and finished products in the picturesque town of Szentendre, just a short drive or train ride north of Budapest on the Danube River. Here is a website link.

To end our visit at the Kovács studio, here is a tribute photo of the elder Mr. Kovács, who during his boyhood in the 1920's was immersed in the world of his family's blue-dying business, and who continued producing Kékfestö indigo-dyed fabrics for his entire life, while training his own son to continue the trade.

Like his father, the younger Mr. Kovács has trained his daughters to continue when he retires, although I'm sure he has many more years to go, probably well into his 90s..

My last two photos in this post are a little surprise for you. Before falling in love with beading and quilting, my main passion was Hungarian folk dancing. I danced in a performance group for 10 years (and later became one of the group's choreographers), performing at many events in the Seattle area, including Bumbershoot and the Folklife Festival. We also performed at the World's Fair when it was in Vancouver, British Columbia. I and several of the other dancers in the group made most of our costumes using Hungarian fabrics and original costumes as patterns.

It was folk music and dance that first called my heart and soul into Hungary, where I have since spent a cumulative total of well over a year of my life, spaced over 14 different visits so far.

So, here you go. This is me, wearing a costume I made with Kékfestö fabric for performing the dances of the Szatmár region, located in northeastern Hungary. This photo was taken in September, 1986 at the World's Fair in Vancouver, Canada, where we performed on two separate occasions.

And this is me on stage at a festival in Redmond, WA, happy as can be, Hungarian folk music, song and dance, filling me with joy! Michael Kappleman and I are the second couple from the left.

So you see... Kékfestö and I go back a long way. Next, I'll be quilting with it!

*****

My apologies to Hungarians for not using the correct accent mark for the last letter of the Hungarian word Kékfestö. I spent 4 hours trying to do it, but could not get Blogger to accept anything I tried.

Wednesday, December 21, 2016

A Visit to an Indigo Fabric Dying Studio in Hungary

Subscribe to:

Post Comments (Atom)

Great and quite interesting info. As a cultural historian, I love to read about the unique bits of different cultures - always makes my day. Thanks for doing the research and writing up! Jeanne Evans

ReplyDeleteYou are so welcome, Jeanne! I am honored by your comment! Robin

DeleteRobin...this must have been such an amazing treat! What a thrill!

ReplyDeleteI LOVE hearing about family artisans. These are techniques that the world must hold onto...national treasures! As always, this was great reading! Hope to see you soon.❤️Merry Mistletoe!

Great, Marie! I'm glad you liked it. And, Merry Mistletoe back to you!

DeleteThank you for the nice report on your trip to the indigo fabric dying. Maybe it is possible to find Kékfestő in google maps and then copy and paste the name into your story :-)

ReplyDeleteGive my regards to Lunnette. I see she is doing well.

Fascinating post ! And I love the picture of you at the end. Wishing you a very happy and healthy New Year full of creative fun, with love. Helene H

ReplyDeleteI especially liked seeing the photos of you from you days of dancing. You are so beautiful Robin, then and now.

ReplyDeleteI recently acquired some of this fabric with the information paper. I was wondering if you had quilted with it and how the dye was performing?

ReplyDelete